I am currently in my last rotation and during this Elkem Trainee Program I had the chance to focus on various innovation topics: Circular Economy, Digitalization, Technology scouting, R&D Process…

One aspect that followed me through the different periods is the collaboration with start-ups.

In 2025, start-ups will rank as top innovation sources for organizations[1]. Therefore, as a large company who wants to push further our innovation limit, collaboration with this type of partner is key.

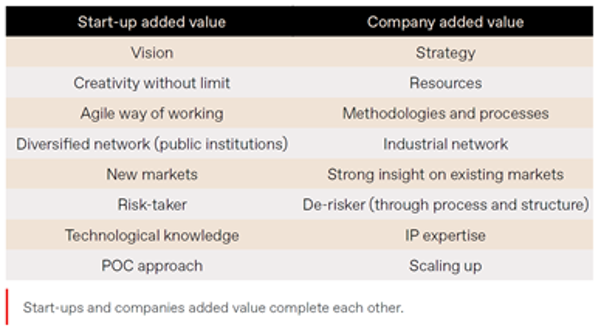

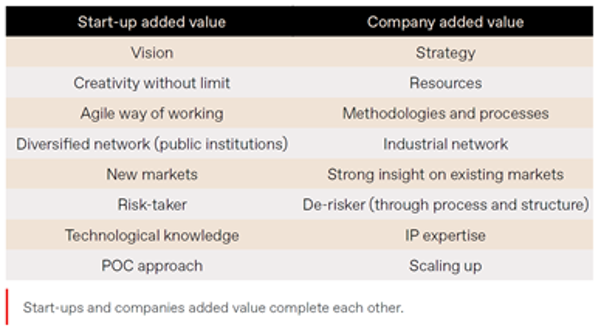

There are multiple ways for an international company and a start-up to collaborate, they actually have a lot of synergies. Complementarities of large companies and start-ups are very well described in literature, and that are summarized in the following table. (POC = Proof of concept)

The items in this table show that the competences required are various and are switching from technology and scientific based, to process and methodologies, relationship and behaviour skills. It is a great learning opportunity for a Trainee! Let’s come back to the different start-up’s experiences:

- A start-up from Norsk Katapult[2] and material catapult: Naomi[3]

The purpose of Norsk Katapult is to ease the innovation process of a company so that they can develop prototypes, test and iterate faster. They, for example, connect start-ups with larger companies, and Elkem is part of the “Future Materials Centers” [4]. Naomi was created by an entrepreneur that offers Silicones plates for children. She wanted to learn about the material she was using, understand better their chemistry and performances, but also their environmental impact.

This mission, that sounds rather easy at first, is challenging:

- Connect Elkem experts: One of the challenges was to bridge knowledge and expertise through the different divisions at Elkem, from the metallurgical Elkem (Norway) to the chemical Elkem (France). It is key to find the right expert, have them understand the aim of the partnership, and make sure that this bridge lasts over time.

- Share technical information with clarity: Being clear does not mean simplify or generalize. It is about translating and adapting the language to find a common base. It is about classifying the information and building up an understanding. It is important to be transparent on the benchmark and the competitor environment. And when it comes to sustainability, we have to stay fact-based to avoid any greenwashing.

- Giving leverages to the entrepreneur: Elin needed selling points for her branding, answers for her customers and a checklist to evaluate the suppliers and materials. To build this argument, I had to think as a consumer, not as a supplier.

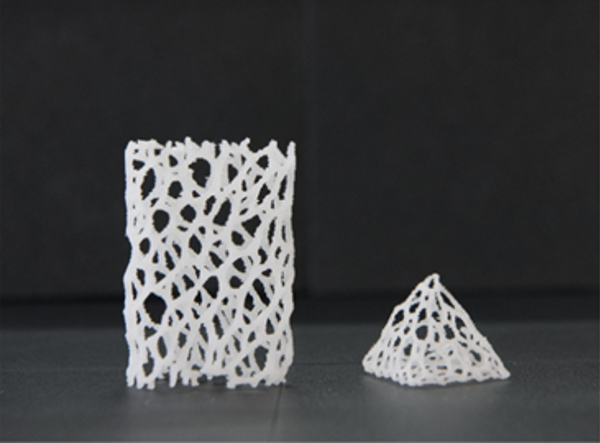

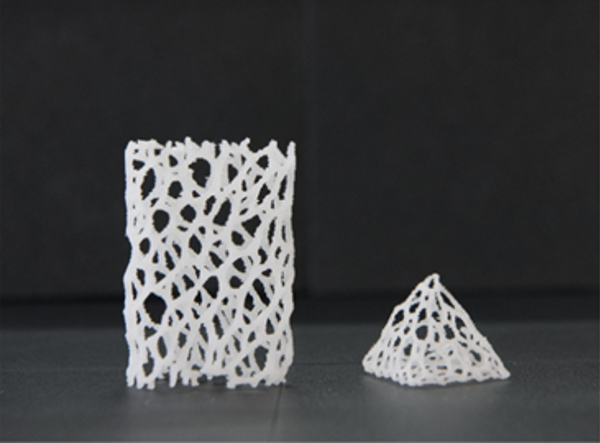

- A start-up coming from an academic lab - 3D printing: 3DeusDynamics[5]

3DeusDynamics is a deep tech start-up that has developed a unique additive manufacturing process called “Dynamic Molding”, pushing the limits of 3D printing manufacturing process. Elkem Silicones started the collaboration with the 3DFab lab in the very early development stages of the technology and supported its maturation, until the creation of the start-up 3DeusDynamics.

This collaboration gave us the opportunity to come back on the learnings of Elkem Silicones and their Open Innovation Strategy, leading to the publication of a white paper “Open Innovation tingles our future”, referenced earlier.

As stated in the white paper, the objective for Elkem Silicones was to participate and help to mature a start-up project.

“The motivation in such collaboration lies in:

1.Partnership with 3Deus Dynamics on an R&D aspect, which enabled Elkem Silicones to push the limit of 3D printing capabilities, and to answer new technical challenges.

- Mutualization of resources to move forward together (intellectual property, market, business models, …).

- Creation of a start-up was the final objective, enabling the technology to grow with several players.”

I applied the innovation tools (9box, innovative market segmentation) to a new technology and to build with the 3DeusDynamic Teams different business models scenarios and marketing strategies. I could attend and follow the creation of the start-up and the investment fund raising.

- A start-up coming out of Elkem – Battery Material: Vianode[6]

Vianode is producing synthetic graphite which is an active anode material for EV Lithium-ion battery. It is a material of choice because the anode will affect the safety, charging speed, capacity, and life cycle of a battery. The technology development started as an internal project at Elkem, and after a maturation, Vianode is today an established company with Elkem ownership. It benefits from the culture of Elkem while remaining an agile start-up.

Vianode is positioned as a leader in the fast-growing battery industry and needs to strengthen as much as possible its competitive advantage. A key leverage to do so, is a strong Intellectual property strategy. It enables to validate the ‘freedom to operate’ of the company, to protect its confidential information, to develop protected solutions and exclude other competitors from using their invention.

It will help Vianode to maintain their technology leadership and leverage interest of more investors.

In the frame of this mission, I am notably:

- Supporting the competitive intelligence and patent watch

- Collaborating with researchers and patent attorneys on patent application writing

- Managing confidentiality agreements and setting up best practices

- Developing trainings on the different topics to raise researchers’ awareness and build a stronger IP culture.

Even though, my final position is not yet defined, I hope that I will be able to work with both established companies and start-ups. It enables to work on technical collaboration and balanced relationships. Of course, I would like to thank my colleagues and the partners that took part to these projects, and that challenged me, supported me. Thanks to them, I had the chance to start developing a strong open innovation network and to learn how to use it. No need to say, that I’m convinced by the necessity of such collaboration and that I was thrilled by these learning opportunities.

[1] The next big thing to boost your innovation – the venture client model | Capgemini

[2] https://norskkatapult.no/

[3] https://www.naomiwithlove.com/pages/about-us

[4] https://www.futurematerials.no/

[5] https://3deusdynamics.com/

[6] https://www.vianode.com/